Understanding the Core of Flexographic Printing

In the world of flexographic printing, the anilox roll is one of the most critical yet least understood components. Often referred to as the “heart” of the press, it precisely controls the amount of ink transferred to the printing plate, ultimately determining the amount that reaches the substrate. But what actually happens inside an anilox roll, and why does it matter so much?

The Role of the Anilox Roll

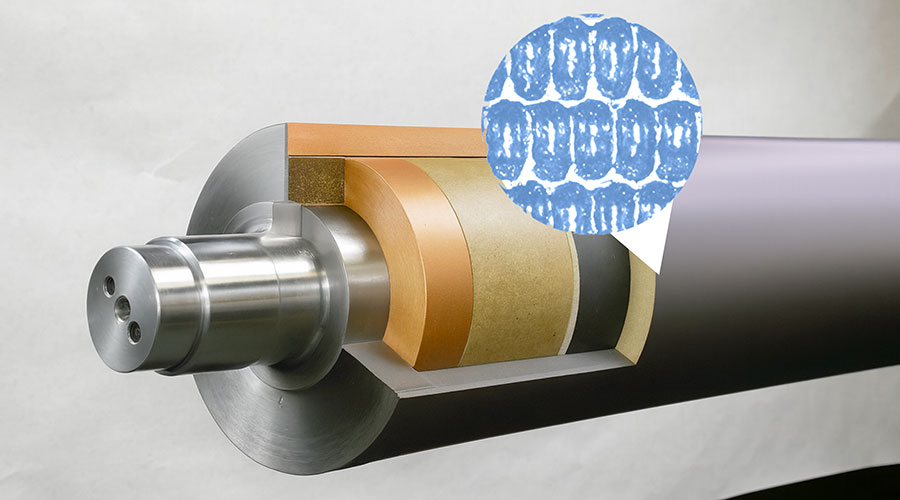

An anilox roll is a hard cylinder, typically made of steel or aluminum, and coated with a layer of ceramic. Its surface is engraved with millions of microscopic cells that hold and meter ink. The size, shape, and volume of these cells determine the amount of ink delivered, a key factor in achieving consistent print quality and color accuracy.

Each rotation of the anilox roll picks up ink from the chamber, and the doctor blade removes the excess, leaving only the precise amount of ink within the engraved cells. As the roll contacts the printing plate, those tiny cells release ink evenly, ensuring sharp, repeatable results.

How Cell Design Impacts Performance

The engraving pattern directly affects how ink behaves on press. For instance, hexagonal engravings promote uniform ink transfer, while elongated cells are better suited for high-viscosity coatings. Selecting the right cell volume and pattern is crucial for achieving a balance between density, coverage, and detail.

Pamarco’s advanced engraving technologies, such as EFlo, are engineered to optimize ink release while minimizing wear, providing exceptional consistency across long production runs.

Common Pitfalls in Ink Transfer

Improper cleaning, worn doctor blades, or volume loss due to plugging can all compromise performance. When ink fails to release uniformly, operators may overcompensate, leading to waste, downtime, and print variation. Routine audits and proper care are the most effective ways to maintain optimal anilox performance.

The Bottom Line

Inside every anilox roll lies the precision that drives flexographic success. Understanding how it works and how to care for it is the foundation of consistent, high-quality print.

Pamarco continues to lead the industry in anilox design, coating innovation, and technical expertise — helping printers worldwide achieve the highest standards in efficiency and quality.