In the world of high-quality printing, achieving precise, repeatable results is a constant challenge. The banded roll test is an effective method for optimizing graphics and press performance. This test provides valuable data that helps printers fine-tune their processes, improving ink transfer efficiency and print quality.

Understanding Banded Roll Tests

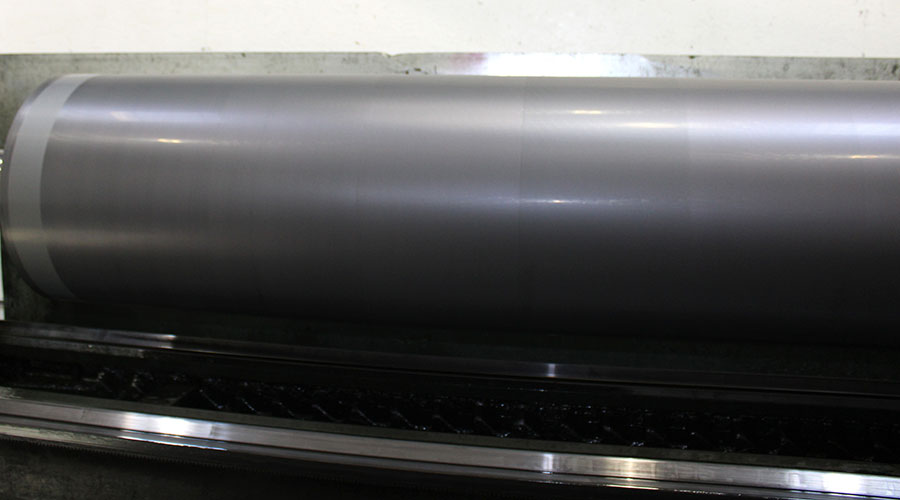

A banded roll test is a structured evaluation that measures ink transfer efficiency across different engraving patterns, angles, and volumes. The goal is to identify the optimal conditions for applying the thinnest possible ink film while maintaining high-quality, repeatable results. Printers can make informed decisions about anilox roll configurations, ink formulations, and press settings to achieve the best possible output by conducting this test.

Preparation Before a Banded Roll Test

Before conducting a banded roll test, it is essential to follow a few key preparatory steps:

- Identify the Substrates – Determine the materials for testing, ensuring they align with the intended printing applications.

- Set Objectives – Clearly define what you aim to achieve with the test, whether it is improving ink transfer, reducing waste, or gaining more consistent colors.

- Consult with Key Suppliers – Collaborate with your press operators, prepress team, ink suppliers, and anilox manufacturers to align expectations and gather input on best practices.

Conducting the Test

During the banded roll trial, multiple engraving patterns, screen angles, and volume configurations are tested to assess their impact on ink transfer. For example, a 60-degree, 400 lines per inch (lpi), 4-bcm anilox roll may be compared against an Eflo or a 30-degree engraving with the same volume. These variations provide data on which configuration offers the most efficient and precise ink laydown.

Benefits of a Banded Roll Test

By conducting a banded roll test, printing facilities can achieve several advantages:

- Optimized Ink Transfer – Identifying the best roll engraving improves efficiency and reduces ink consumption.

- Repeatable Print Results – A well-balanced, optimized press setup leads to consistent high-quality output across multiple print runs.

- Reduced Press Make-Ready Time – A refined printing process minimizes setup time, leading to faster production and cost savings.

- Enhanced Print Quality – By selecting the best engraving pattern and ink film thickness, printers can achieve sharper, more vibrant graphics with minimal dot gain.

Conclusion

A banded roll test is essential for printers looking to enhance graphic precision and production efficiency. By systematically evaluating different engraving configurations and ink transfer characteristics, print professionals can ensure their presses operate at peak performance. Investing time in these tests improves consistency, cost efficiency, and superior print quality in the long run.