How much time do your operators spend each day manually knifing ink into the fountain? How much ink is wasted through overfilling, skinning, or simply being left behind in the can? According to industry analysts, up to 20% of ink in every can never makes it to the sheet.

And that’s just the beginning. After refilling ink, how many sheets are wasted trying to reestablish color consistency? Color variation remains the number one cause of rework. Add in the costs from repetitive strain injuries like carpal tunnel, downtime from accidents, and other inefficiencies, and the losses quickly pile up.

In a competitive market, can you really afford to ignore them?

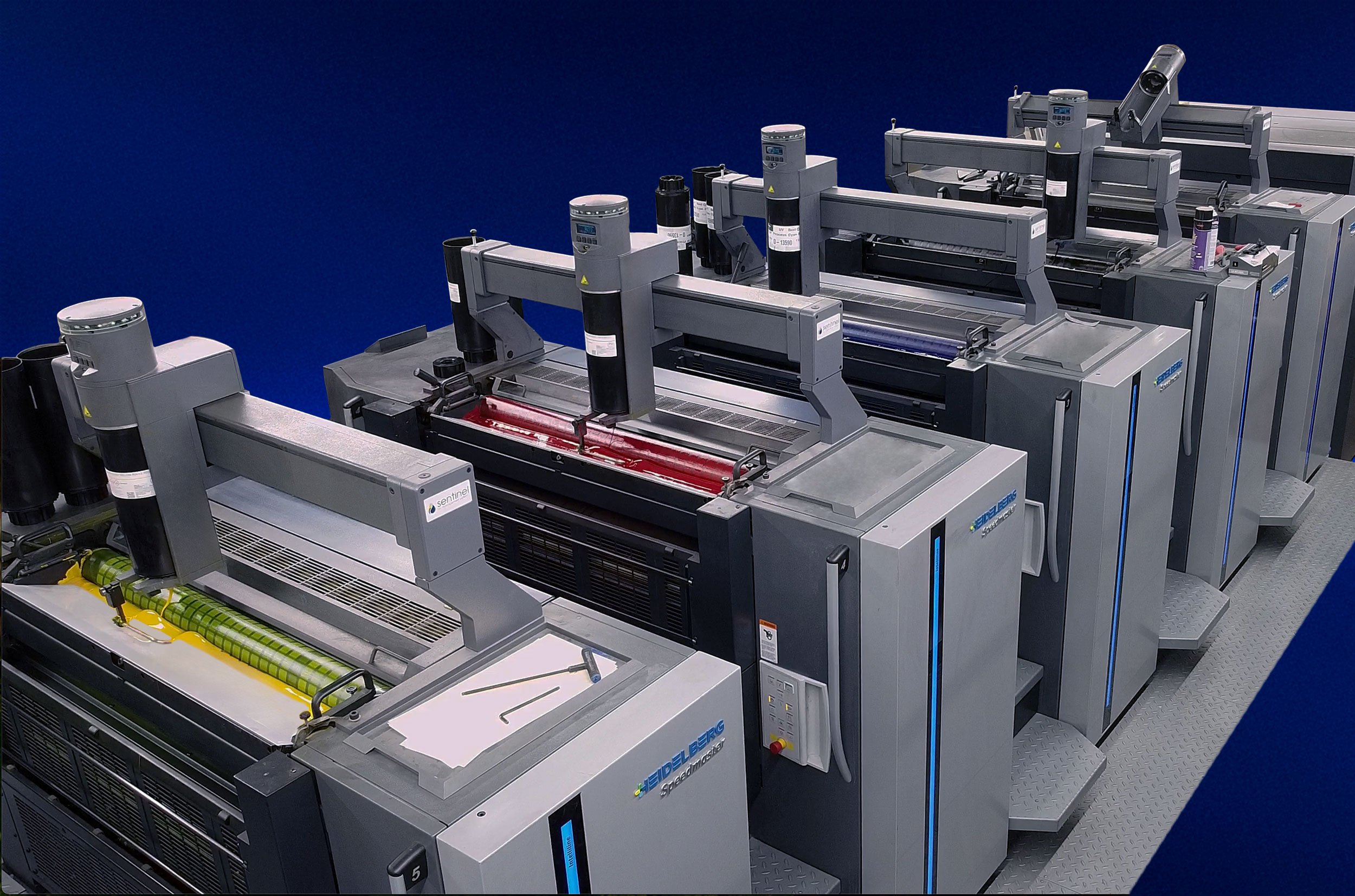

Meet the Sentinel Ink Management System

The Sentinel System is a revolutionary, computer-controlled, fully automated ink dispensing solution that puts you back in control. Using ultrasonic sensors, Sentinel constantly monitors ink levels across the entire fountain and automatically dispenses the right amount of ink exactly when and where it’s needed.

Smart Canisters. Smarter Workflow.

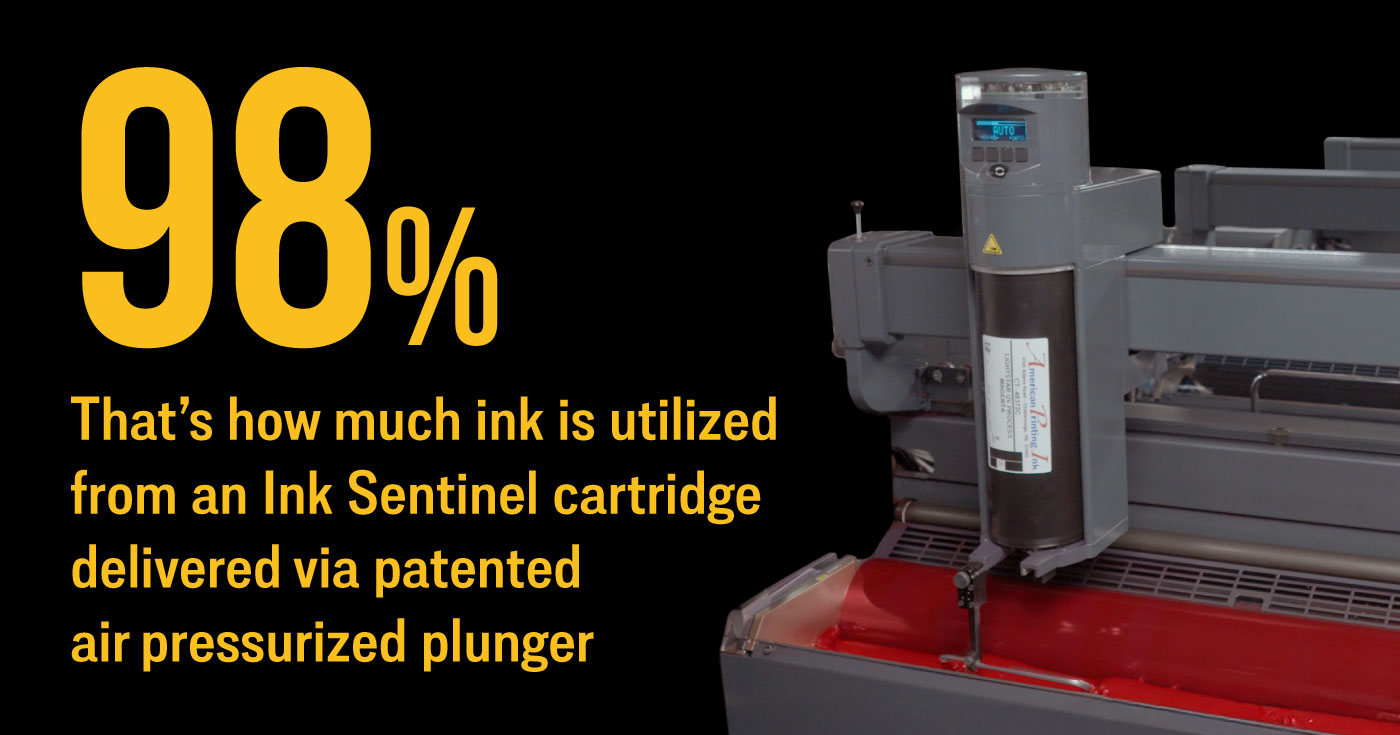

Sentinel uses readily available 8lb (3.6kg) cartridges from Sonoco and Ritter, which can be prefilled by any ink manufacturer. Swapping them out takes less than 10 seconds — no shutdowns, no system interruptions. A reliable stepper motor and belt drive move the dispensing head smoothly across the fountain, while ink is delivered via air pressure, pushing a plunger that scrapes out over 98% of the ink.

Unused ink? When not in use the canisters are sealed to allow the ink to be stored for future use.

The Results Are Real

Estimates show that switching from cans to canisters could save over 25 million pounds of ink annually across the industry. Sentinel makes those savings tangible, delivering benefits like:

- Reduced ink and paper waste

- Lower make-ready times

- Fewer man-hours spent on manual labor

- Improved ergonomics and operator safety

- Higher consistency and color accuracy

With features like LED and audible alerts, real-time usage stats, and job-end reporting, Sentinel also helps you create more competitive job estimates and increased accuracy of VOC tracking.

Built For Demanding Production

Designed to withstand the rigors of high-volume shops, Sentinel handles heavy UV inks and harsh wash-ups with ease. Installation is fast, requires no press modifications, and delivers immediate savings.

Sentinel pays for itself in under a year—and keeps saving you money long after that. It's time to replace messy, wasteful manual inking with a smarter solution.

Contact us today to see what Sentinel can do for your operation.