Our Mission

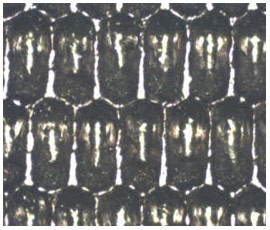

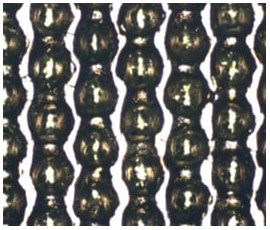

Since 1946, Pamarco has been at the forefront of anilox technology, evolving from Paper Machinery & Research Corporation, founded by David Killary and Bill Donohue, into the industry’s only full-service global provider. Our expertise spans anilox rolls, accessories, cleaning solutions, and professional roll audits—all designed to enhance your print performance. For nearly 80 years, we’ve empowered businesses like yours to achieve peak operational performance. That’s just how we roll.

Building on decades of proven success and innovation, Pamarco passionately strives to be the preferred, trusted supplier of world-class sustainable products and services for the packaging and print industries.